Society

Strengthening of Human Capital Management

Aichi Steel believes that its mission is to accurately identify the changing needs of society and continue to provide new value as a materials manufacturer, amidst highly uncertain circumstances such as the rapid progress of decarbonization. We also consider our human capital to be the source of our success in this mission.

We are working to strengthen our human capital management to achieve corporate growth. In these efforts, we leverage the Aichi Way, which has been passed down through generations as a set of values to be cherished in our work, and the technologies and skills we have cultivated as a materials manufacturer, to help each and every employee maximize their potential by acquiring skills corresponding to changing roles and taking on new challenges with enthusiasm. Our human resources development aims to create a group of top-notch professionals who strengthen their fundamentals and refine their skills. More specifically, at the foundation of this effort is the creation of opportunities and systems that enable the success of diverse human resources, improvement of engagement between individuals and the company, and the development of the base where people naturally grow, all in workplace environments ensuring good health, safety, and security.

Diversity and inclusion

Aichi Steel believes that employees with diverse values, potentials, and experiences understanding each other, enhancing each other's potential, and demonstrating it will lead to the creation of new value. This is why we are committed to the employment of diverse human resources and the development of systems and environments that enable them to demonstrate their abilities.

Promotion of more active roles for women in the workplace

Aichi Steel is committed to creating an environment in which women can choose flexible workstyles to pursue their goals. We support career development through training and other measures, and have introduced and developed systems to help women balance work and life events. These include the Nice Family System, which is centered on childcare and nursing care support systems, as well as flextime system without a core period and working from home system. We are also focusing on efforts to raise awareness, such as providing e-learning on childcare support systems to all managers to promote understanding among superiors and other employees in the workplace, and to create an environment that facilitates the use of childcare leave regardless of gender. In fiscal 2022, 22 male employees, double the number of the previous year, took childcare leave, indicating the positive effects of our efforts. We will continue to respect diverse values, promote the creation of an environment in which everyone can play an active role regardless of gender, and work to create an environment in which all employees can balance work with their personal lives.

Overview of the Nice Family System

| FY2022 | ||

|---|---|---|

| Rate (and number) of female managers*1 | 1.0% (4) | |

| Rate (and number) of male employees taking childcare leave*2 | 33.3% (22) | |

| Wage difference between male and female employees*1, *3 (%) | All employees | 66.5% |

| Full-time employees | 68.2% | |

| Part-time/temporary employees | 68.7% | |

- Calculated based on the provisions of the Act on Promotion of Women's Participation and Advancement in the Workplace

- The percentage of employees taking childcare and other leaves under Article 71-4, Item 1 of the Ordinance for Enforcement of the Act on Childcare Leave, Caregiver Leave, and Other Measures for the Welfare of Workers Caring for Children or Other Family Members is calculated based on the provisions of the ordinance.

- Aichi Steel's salary and evaluation systems do not vary by gender, and the factors that contribute to differences in wages between men and women are the length of service, the ratio of women in manager positions, and the ratio of men and women in different job categories with different salary levels.

Success of older employees

The number of older employees (aged 60 and above) is expected to increase in the future due to the future decline in the labor force, increase in the age at which pension benefits begin to be paid, and retention and improvement of workplace capabilities. Aichi Steel has established the Nice Senior System, which allows all employees who wish to continue working beyond the age of retirement until the start of pension benefits. Through discussions between labor and management, we have created comfortable work environments and revised employee benefits to ensure that older employees can continue to work with joy. In addition, to provide an opportunity to review their plans for post-retirement life, we are also implementing initiatives for the autonomous career development of older employees, such as holding seminars for those who have reached the age of 55 on themes such as how to work, retirement benefits and pensions, and health and dietary habits.

Expansion of active workplaces for people with disabilities

Aichi Steel is implementing a variety of measures to enable employees with disabilities to play an active role in a wide range of workplaces, including manufacturing sites and administrative divisions. With a focus on motivation, individual characteristics, and suitability for the operations, we determine assignments based on a series of practical workplace training and interviews. We are also implementing measures to fully utilize the potential of employees with disabilities after assignment, such as regular meetings with the employee concerned, follow-up with their workplaces, and other support and consideration led by the Vocational Life Consultants for Persons with Disabilities. In addition, to eliminate obstacles making it difficult for employees with disabilities to work, we are also committed to expanding the number of workplaces available to them through the introduction of barrier-free facilities, support for career advancement, and initiatives to raise employees' awareness and improve understanding.

Mid-career recruitment

In today's increasingly complex society, Aichi Steel believes that solving social issues through our business requires more advanced knowledge, diverse experience, and abilities than ever before. For this reason, we are focusing on mid-career recruitment, especially in our priority areas.

In fiscal 2022, we hired 16 employees in general positions. (Rate of mid-career recruitment: 44.8%)

Human Resources Development

Aichi Steel is committed to developing human resources who can improve their basic skills, which are indispensable regardless of the times, and their expertise necessary to adapt to changes, and are able to think and act independently, while practicing the Aichi Way, a set of shared values that must be held by all employees of the Aichi Steel Group whose key words are "Sustain," "Appreciate," and "Create."

Implementation of the Aichi Way

Aichi Steel's human resources development is based on the concept of the Aichi Way, which is to "sustain" the skills and spirit established by our predecessors, to "appreciate" the colleagues, and to continue to "create" for the benefit of society, people, and colleagues.

Strengthening of basic skills and expertise

To strengthen the basic skills required for our operations, Aichi Steel is focusing on three areas: problem-solving capabilities, which are the foundation of work, skills for strong workplace capabilities, and digital literacy, which has been newly added. Our basic approach is to acquire problem-solving capabilities and skills through on-the-job training based on the principle of "Genchi-Genbutsu,"* and to enhance their effectiveness through off-the-job training (group education and training, etc.). For digital literacy education, we provide a flexible training program centered on e-learning, offering an educational curriculum suited to each individual's level of proficiency. In addition, to support self-development efforts, we provide correspondence courses, study assistance, and certification incentive programs to strengthen expertise.

- "Genchi" is actual place (Gemba) and "Genbustu" is actual stuff or goods, something you can physically touch

Skill improvement

We conducted PM practical skill training as part of rank-based training to improve employees' specialized knowledge and skills required for execution of operation. In addition, we support skill improvement by providing incentives, training environments, and information for technical skill tests that employees voluntarily take on.

Number of training instructors trained (cumulative)

Number of persons who passed the technical skill test

On-the-job and off-the-job training

Aichi Steel is actively and systematically practicing on-the-job training from the viewpoint that experience in and learning from onsite inspections are the key to developing human resources. We have established a system in which each employee reviews their future career plan and regularly discusses with their superior their work assignments and goals for acquiring the skills and knowledge necessary to realize the plan and for developing competencies. In training programs, various efforts are made to enhance the effectiveness of training, such as senior employees taking charge of instructing junior employees to achieve a synergistic effect between on-the-job training and off-the-job training, and top management providing messages based on their own experiences to raise participants' motivation.

Digital literacy education

To adapt to the rapidly changing business environment and maintain and improve competitiveness, it is necessary to promote DX for the transformation of the operations, organizations, and corporate culture, in addition to initiatives at manufacturing sites, such as smart factories. To achieve this, Aichi Steel has introduced a new education program to accelerate efforts to develop DX human resources. In fiscal 2022, we conducted digital knowledge training, mainly through e-learning, for all employees in general positions. From fiscal 2023, we are focusing on the selection and training of DX leaders who will drive DX promotion.

Efforts to develop human resources for executives

To systematically develop human resources who will be responsible for future management, Aichi Steel provides education programs to acquire managerial leadership skills that allow them to see and think from the perspective of the entire company to create management ideas, and to hone their boldness, vision, sense of speed, and other qualities necessary for assuming higher responsibilities. Having the managing executive officers serve as instructors, the programs are designed to make the participants aware that they are core human resources, with an emphasis on their mindset to fulfill their roles. By continuously striving to develop human resources for management, we will ensure that we have the human resources to support the management of the company.

Health and Safety Initiatives

Basic approach

Since its foundation, Aichi Steel has practiced people-oriented management. People-oriented management refers to management that enables employees to lead healthy and active lives, both physically and mentally, to realize valuable lives and the happiness of employees and their families, and provides value to society. Based on the basic philosophy that health and safety take priority over all, we position employee health and safety as priority issues, work to maintain and improve their mental and physical health, and create people-friendly, safe, and secure workplaces.

Implementation of health and productivity management

Aichi Steel believes that efforts to maintain and improve employee health bring a range of benefits, including vitality and productivity improvements for the organization. Based on this belief, we are committed to implementing health and productivity management for sustainable growth. In the Medium-term Management Plan, we have established quantitative targets for employee health and have been working on continuous improvement through PDCA cycles. With mental health and the prevention of lifestyle-related diseases as our priority issues, we are working to enhance various measures by promoting "collaborative health"* through collaboration among the company, Health Insurance Society, and labor union. In recognition of these initiatives, we were recognized for the sixth consecutive year in 2023 as a Certified Health & Productivity Management Outstanding Organization.

- Efficient and effective implementation of disease prevention and health promotion for insured individuals through active collaboration between the insurer and the business with clearly assigned roles and favorable workplace environments

Promotion structures

Prevention of lifestyle-related diseases

With the aim of improving lifestyle habits for better health, Aichi Steel is promoting Health Challenge 8 initiatives to raise employees' health awareness and encourage behavioral changes. Employees and workplaces voluntarily engage in health promotion activities in a fun and creative way by holding inter-office events to encourage the implementation of healthy habits related to the eight categories: maintaining appropriate weight, eating breakfast, drinking alcohol, snacking between meals, giving up smoking, doing exercise, sleeping, and reducing stress.

Mental health

Aichi Steel is working to prevent the occurrence of mental health issues and ensure their early detection and care by establishing a Mental Health Consulting Counter, providing education to both regular employees and supervisors, and providing consultations with a medical adviser on mental health for employees with mental health issues. In addition, we conduct stress checks once a year for all employees, and promote mental health by providing care for high-stress individuals and high-risk workplaces.

Harassment

Harassment is not only an assault to personal dignity and a disturbance of the peace in workplaces, but it is a problem that severely impacts business management as well. This is why labor and management are working together to create harassment-free workplaces. Aichi Steel established the Aichi Steel Harassment Prevention Guidelines, which defined measures for preventing harassment and rules for the company and employees to observe, and provide education to all executive officers and employees. We have also established dedicated consultation contact points internally and externally to address harassment issues, and we are allocating consultants in each workplace to systematically suppress harassment while achieving early detection and resolution. Consultations, reports, and issues uncovered are quickly examined, and facts are confirmed, in the Investigative Committee made up of members of labor and management who work to prevent recurrence through strict measures, education of supervisors, and other actions. In fiscal 2022, we increased the number of Workplace Advisers in remote areas and workplaces with rotating shifts for the purpose of increasing the convenience and effectiveness of these advisers, who are set up to support and serve as guides for workplace development. We are also working to raise awareness about harassment by regularly publishing a Labor Affairs News on harassment.

Basic conceptual diagram of harassment prevention structures

Safety

Basic approach

The Aichi Steel Group recognizes that safety takes priority over all. With this approach in mind, in accordance with the Basic Philosophy for Safety and Health, we aim to create safe and secure workplace environments for our employees and everyone else on our premises and to transform into a company with a safety culture.

Basic Philosophy for Safety and Health

Safe work, Reliable work, Skilled work. Safe work is "the gate" to all work. Let us pass through this gate.

Promotion structures

Led by the Safety & Environmental Division which is directly supervised by the president, the Aichi Steel Group is working on reducing and preventing occupational accidents, fostering safety-conscious human resources, and conducting inspections and audits. Based on the belief that all accidents and injuries can be eliminated, we are working to create safe and healthy workplace environments for all workers on our premises by sharing companywide policies not only with the in-house companies, headquarters, and Group companies, but also with cooperating companies.

Activity policy

To prevent accidents, the Aichi Steel Group is developing safety activities based on the three pillars: safety management, fundamentally safe designs, and the development of safety-conscious human resources.

Fiscal 2022 initiatives

Safety management

Safety Convention

The Safety Convention is held in conjunction with National Safety Week to share information on occupational accidents and to establish common policies for activities.

Onsite support

This initiative promotes accident prevention activities by supporting the activities of all workers on our premises by proposing better work practices and improving problems.

Fundamentally safe designs

Management Safety Inspection Meeting

This initiative promotes the horizontal implementation of safety initiatives through guidance on and sharing of measures to eliminate hazardous sources specific to the workplace based on onsite inspections by top management.

Learning and sharing of past accidents

This initiative aims to prevent the recurrence of similar accidents by inspecting the status of countermeasures for accidents that occurred in the past.

Development of safety-conscious human resources

Skill competition

This competition is designed to raise the level of our daily safety awareness and skill training by confirming and improving this level through competition.

Prevention of disasters and accidents from being forgotten

This initiative strives to develop autonomous human resources by learning about the true causes of accidents and sustaining the mindset to be applied to autonomous actions.

Number of lost time accidents and lost time frequency rate

Creation of a Comfortable Work Culture

Basic approach

For the company and employees to share goals, grow together, and for each employee to demonstrate their full potential, a high level of engagement and a comfortable workplace culture are necessary. To achieve this, Aichi Steel conducts regular employee engagement surveys and implements necessary measures to ensure that employees feel a sense of growth through their work, remain motivated to work, and feel more fulfilled in their jobs. We are also working to enhance safe and comfortable work environments, such as by improving office environments, cafeteria, and restrooms.

Examples of activities

| Category | Examples |

|---|---|

| Communication |

|

| Workplace environments |

|

| Benefits and welfare |

|

- A system that allows employees to select their favorite benefits from a menu of benefits within the points allotted to them

| Lifestyle support |

|

|---|---|

| Health support |

|

| Housing support |

|

| Childcare and nursing care support |

|

| Refreshment support |

|

| Asset building and insurance support |

|

| Diverse workstyle support |

|

| Self-development support |

|

Changes in engagement evaluation

Initiatives to improve engagement

Aichi Steel conducts an annual engagement survey of all employees. Based on the results of the analysis from various perspectives, such as motivation toward work, sense of growth through work, support from superiors, and workplace culture, we are working to develop various personnel measures and improve management in each workplace. In addition, for managers, who play an important role in workplace development, we are working to improve their management skills through lectures by experts and leadership training. In fiscal 2023, to gain a deeper understanding of the analysis of each workplace and clarify the direction of improvement, we are working to create a better workplace culture aimed at employee happiness and growth by starting to improve the engagement survey.

Research and development initiatives

Areas of contribution through research and development

Based on Vision 2030, Aichi Steel is committed to developing functional products for the next generation to contribute to renewable energy, healthy living, food security, and safe public and transportation systems, with the aim of solving social issues through its business. In our development vision 2030, we have designated autonomous driving, electrification of automobiles, energy, food, and health and safety as our five priority areas, and we are focusing on the development of next-generation mobility and development that enriches people's lives.

Strengths of "integrated forging with steel making processes" and "materials manufacturer"

Aichi Steel utilizes the strengths of its integrated forging with steel making processes, in which a wide variety of components are added to raw steel scrap to create specialty steel with properties and functions such as strength and heat resistance, and then finished into forged products, and the knowledge it has accumulated as a materials manufacturer since its founding, to develop products that address to changes in society and meet the needs of society.

Development based on integrated forging with steel making processes

Expansion of material technologies

Initiatives in standardization activities

Aichi Steel is focusing on standardization activities as efforts to widely share the results of research and development with society. Establishing standards and specifications for new products and technologies is essential for ensuring quality and reliability, leading to greater customer satisfaction and smoother market introduction. We have established internal structures to promote standardization activities.

Promotion structures for standardization

Aichi Steel is promoting standardization activities through the Standardization Promotion Committee. The committee is chaired by the Research and Development Headquarters general manager, who is in charge of research and development, as the chief standardization officer (CSO), with general managers of the Business Management Departments of each in-house company and general managers of each Development Division as persons in charge of each division, and the representative managers of each department in charge as members of the committee. Going forward, the committee will focus on promoting strategic standardization activities, as well as raising awareness within the company and fostering standardization personnel.

Standardization Promotion Committee

Intellectual Property-related Initiatives

Basic policy

Aichi Steel has established proactive intellectual property (business expansion and challenges), defensive intellectual property (business stability), and basic activities (human resources development and structure building) as its priority policies, setting targets for each and working to promote intellectual property activities that lead to steady growth.

Promotion structures

Aichi Steel has established an Intellectual Property Committee to promote intellectual property activities. The committee is chaired by the Research and Development Headquarters general manager, with general managers of each in-house company, headquarters, and technology division as members.

Intellectual Property Committee

Enhancement of new business patents

In the past, Aichi Steel focused on protecting intellectual property that is the result of research and development. In recent years, however, our development and intellectual property divisions have also been strengthening their collaboration and working to improve the quality of our patent applications through strategic patent applications that lead to the creation of new value. In particular, we are focusing on new business-related fields and increasing the number of high-quality patents we hold. We will continue to promote activities aimed at building a patent portfolio that helps us to secure our superiority as a company and expand new businesses.

Changes in the number of patents held

New Business Creation Initiatives

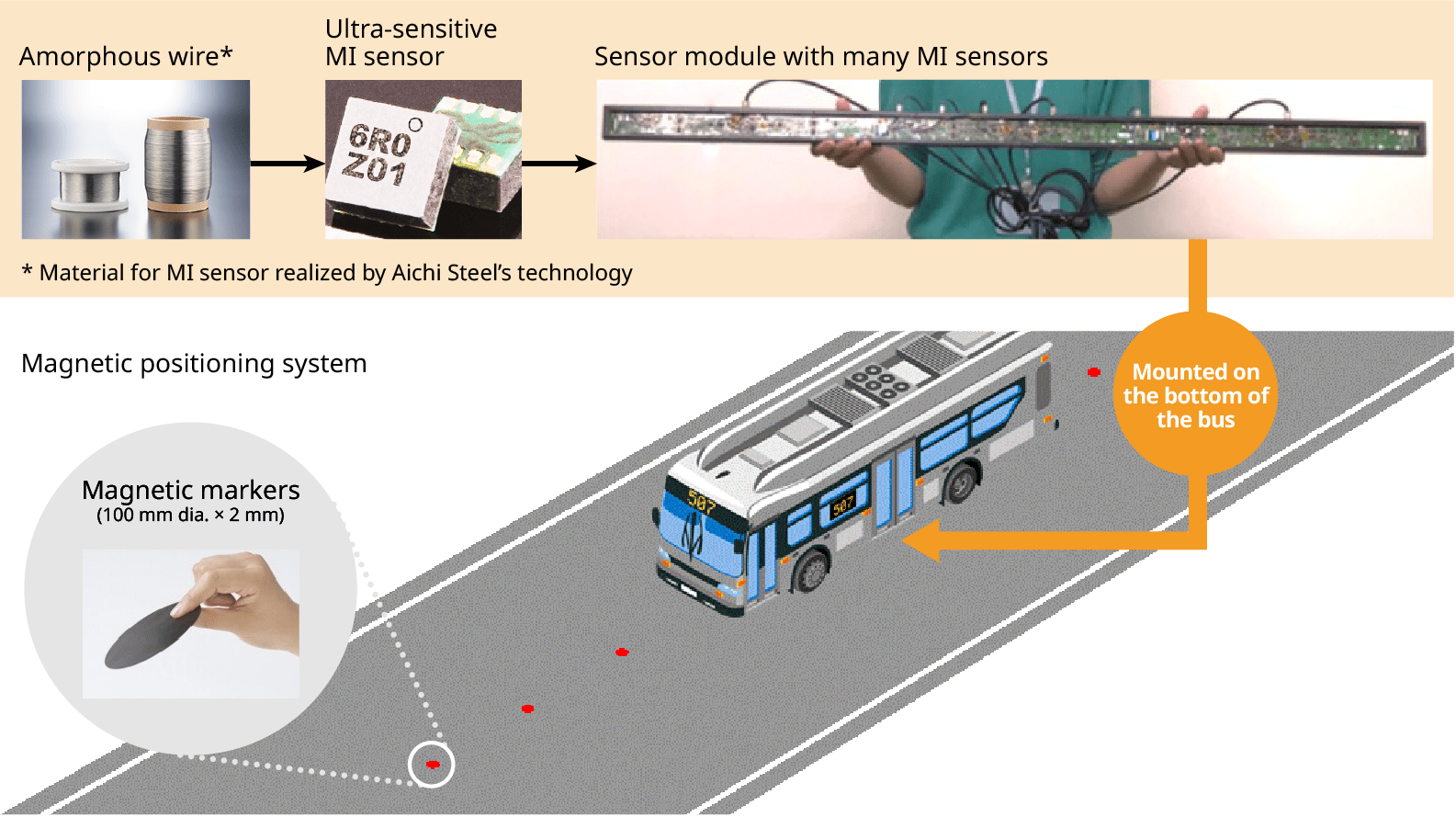

Autonomous driving made possible by GMPS

Aichi Steel is working toward the development and early commercialization of the Global Magnetic Positioning System (GMPS), an autonomous driving support system that uses our proprietary magneto-impedance (MI) sensors to detect magnetic markers placed on roads, enabling the estimation of automotive positions with high accuracy on the millimeter scale even in harsh environments. Since 2017, we have conducted verification trials in various locations and environments with national and local governments, private companies, and organizations, and have received high ratings in terms of performance and reliability. In December 2022, as the first example of social implementation, GMPS was adopted for use in an autonomous driving bus operating between Yanaizu Station and Rikuzen-Yokoyama Station on JR East's Kesennuma Line bus rapid transit (BRT). Other applications include the autonomous driving of towing vehicles on plant premises, and many more are expected in the future. We will continue our efforts to realize a safe and secure mobility society by taking advantage of our advanced technical capabilities that have realized ultra-sensitive MI sensors, high-quality and low-cost magnetic markers with the weak magnetic force, and our unique magnetic field noise elimination system.

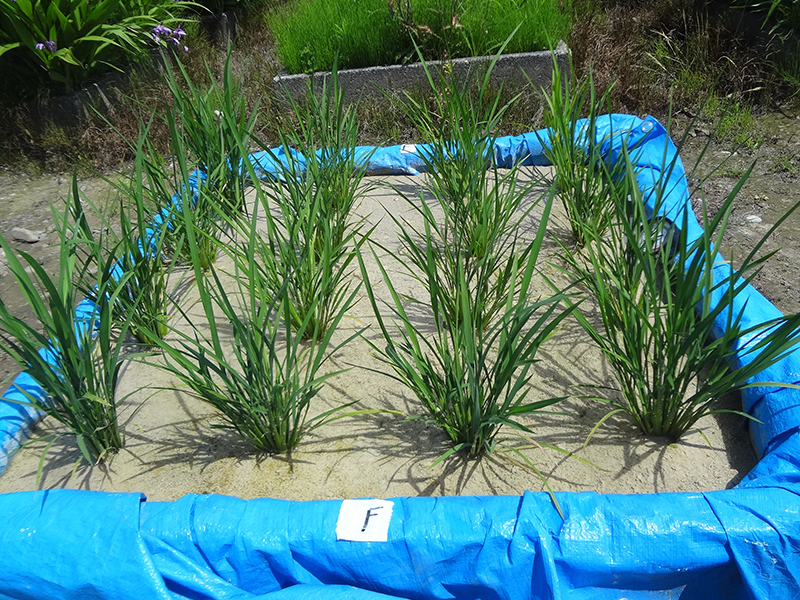

Next-generation iron fertilizer PDMA to increase food production in poor soil

One solution that is attracting attention is to increase food production in poor alkaline soils, which account for about one-third of the world's land area. Aichi Steel has succeeded in developing a next-generation biodegradable iron fertilizer, PDMA, that makes it possible. PDMA has been shown to be effective in promoting the growth of gramineous plants such as corn and rice, as well as non-gramineous plants such as pumpkins and beans. Currently, artificial chelated iron materials are commonly used, but there are concerns about their environmental impact because they remain in the soil. On the other hand, our next-generation iron fertilizer PDMA is biodegradable and decomposes in the soil, resulting in a smaller environmental impact. We are currently conducting cultivation experiments in North America and other parts of the world with the aim of commercialization, as well as working on process development for commercialization.

Implementation of Quality Management and Improvement of the Underlying Manufacturing Capabilities

Aichi Steel has always focused on the manufacturing capabilities of integrated forging with steel making processes, which cover everything from material design to production of steel, forged products, and electronic components. We have continued to provide our customers with highly functional and high-quality materials and parts with high strength, durability, and machinability, which are indispensable in the automotive and other industries. This stable supply of high-quality, low-cost products has been supported by the implementation of quality management and the evolution of manufacturing capabilities through the Toyota Production System (TPS), Total Quality Management (TQM), and Total Productive Maintenance (TPM). Using this as a foundation, we are working to build production systems that are resilient to changes as we face increasing uncertainty, including geopolitical risks and sharp price fluctuations.

TPS Activities

Aichi Steel is striving to improve its lean manufacturing capabilities by promoting cost reduction through thorough elimination of waste based on the two pillars of TPS: just in time and automation. Each in-house company is systematically carrying out this effort by identifying specific issues and improvement themes for cost reductions from the perspective of TPS, and incorporating these activities into the Medium-term Management Plan. We are also focusing on human resources development to put TPS into practice. Selected employees serve as TPS promotion leaders, and under the TPS trainee system, they not only learn knowledge through theoretical lectures but also conduct practical studies such as case studies to apply TPS in their workplaces. Furthermore, to develop human resources for improvement necessary for the smooth introduction of TPS to actual manufacturing sites, we are expanding position-specific education for a wider range of employees and promoting the acquisition of TPS methods required according to their roles. With these cost reduction and human resources development activities as two key elements, we are building production systems that can respond flexibly to times of rapid change.

Improvement themes

| Category | Outline of initiatives |

|---|---|

| Labor-saving | Improvement of single-person productivity per day, consolidation of equipment |

| Shortening of lead time | Reduction of production quantity, streamlining of production |

| Enhancement of production capacity | Reduction of downtime, improvement of specific consumption |

| Reduction of man-hours | Reduction of downtime, shortening of MCT* |

- The time required to machine and assemble a single component

TPS human resources development

TQM activities

Implementation of quality management based on TQM

Based on the basic TQM principles of "customer first," "full participation," and "constant improvement," the Aichi Steel Group is working as one to build a flexible and resilient corporate structure through quality improvement of products and work and vitality Improvement of people and organizations.

Deployment of TQM activities

"Jikotei Kanketsu" with customer first

Based on the concept that quality is built in the process, which was born from Toyota Motor Corporation's manufacturing site, Aichi Steel is promoting "Jikotei Kanketsu" activities to ensure that no defective products are passed on to customers, including those in back-end processes, and that products are always delivered on time to satisfy customers. In addition to manufacturing sites, we are also expanding our activities to our administrative divisions with the aim of strengthening our competitiveness.

QC circle activities with full participation

Aichi Steel is working to establish and expand small-group QC circle activities as a means of improving operations in workplaces. We strive to develop human resources and revitalize organizations by encouraging activity teams to identify problems, clarify issues, and propose the implementation of countermeasures. In fiscal 2022, 163 teams were active in QC circle activities, and 14 cases received external awards. In addition, we are actively engaged in efforts by individuals to propose creative and innovative ideas, and in fiscal 2022, we received approximately 3,000 proposals companywide.

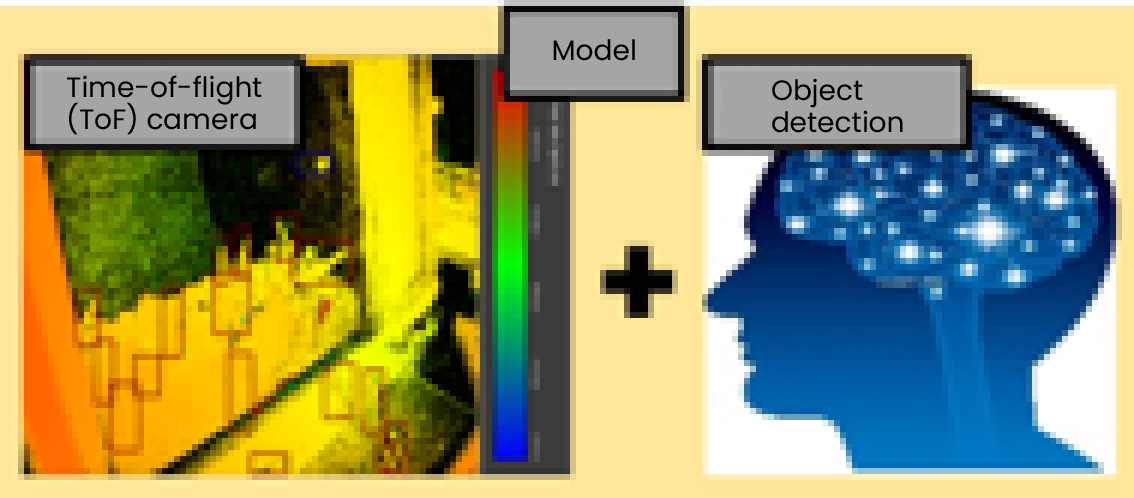

Constant improvement toward technological advancement

The automotive industry is undergoing a once-in-a-century revolutionary change, and the quality requirements are changing along with the shift to electrification and other changes. Aichi Steel is working to develop expert human resources capable of utilizing technologies such as IoT, big data, and AI to maintain and strengthen competitiveness while continuing to adapt to changes in quality. We are working on constant improvement by applying the results of these efforts to equipment error detection, automated inspection using image analysis, and automatic calculation of the grain shape of steel materials.

TPM Activities

With the goal of efficiently producing high-quality products, Aichi Steel is engaged in TPM activities in which all members working onsite participate in maintenance and perform planned maintenance. We aim to achieve zero failures and zero defects by analyzing production facilities, taking countermeasures, and making improvements before failures occur to transform human behavior and onsite facilities. In 2020, we relaunched TPM activities with the aim of raising the level of activities, and restarted activities involving everyone from top management to operators of manufacturing sites, with the three keywords of "full participation," "initial cleanup," and "human resources with strong technical capabilities." With operator self-maintenance as the most important activity, we have set quantitative targets for activities such as zero failures of production facilities, zero quality defects, zero occupational accidents, and productivity improvement through reduction of production losses, leading to the fostering of comfortable workplace environments. We are implementing the activities in line with the TPM Activity Master Plan formulated at the time of the relaunch, and achieving steady results, with 233 employees having acquired level 1 (top grade) self-maintenance personnel certification (acquisition rate: 17.8%) and a 15% reduction in total facility failures (compared to fiscal 2021) in fiscal 2022. Going forward, we aim to further improve our competitiveness by promoting the newly established Aichi-style TPM (data analysis, visualization, and failure reduction by making full use of DX).

TPM Activity Master Plan

Promotion of Dialogue with Stakeholders

Aichi Steel conducts its business activities through relationships with various stakeholders, so building positive relationships with those stakeholders is important for improving corporate value. Through proactive dialogue with stakeholders, we are able to incorporate the needs of society and expectations for us into our business activities, and encourage them to feel a sense of closeness with Aichi Steel. In this way, we are able to grow alongside all of our stakeholders, including customers, shareholders and investors, employees, suppliers, and local communities.

| Stakeholders | Initiatives to promote dialogue | FY2022 achievements |

|---|---|---|

| Customers |

|

Number of inquiries1,399

|

| Shareholders and investors |

|

Number of dialogues

with institutional investors (total) 21 |

| Employees |

|

Number of meetings

between labor and management17 |

| Suppliers |

|

Number of

participating companies113 |

| Local communities |

|

Number of

volunteers (total)6,581 |

Promotion of Dialogue with Employees

To provide value to society and achieve sustainable growth, it is essential for Aichi Steel to ensure a high level of employee engagement, which is the source of value creation. We are promoting initiatives to increase employee engagement by building dialogues with our employees, creating comfortable workplaces, and improving human resources systems. In 2020, the 80th anniversary of our founding, we signed the Declaration on Labor-management Cooperation, in which labor and management mutually confirm and share the goal of overcoming any difficulties through mutual trust between labor and management and aiming for a company full of smiles with everyone involved. In addition, labor-management meetings were reviewed and new labor-management roundtables were newly established at the in-house company and headquarters levels to allow the two parties to more frankly exchange opinions and accelerate reform.

We are making efforts to have labor and management honestly exchange opinions, deepen understanding, and cooperate with each other on familiar issues and countermeasures at the in-house company and headquarters levels. As one of the initiatives for fiscal 2023, labor and management are working on a greeting campaign to revitalize communication after the COVID-19 pandemic. From the perspective of creating diverse, open, and comfortable workplaces, we are also focusing on improving workplace environments for employees to work with peace of mind by conducting a morale survey on all employees, improving rest areas at workplaces, and constructing a multi-story parking garage and new dormitory for single employees.

Strengthening of Relationships with Suppliers

Superior raw materials, parts, and technologies supplied by our suppliers are essential for manufacturing Aichi Steel's products, including specialty steels. We also need to collaborate with our suppliers in addressing various sustainability issues such as carbon neutrality and human rights. We are working to build a relationship of trust with our suppliers through close communication, and to establish and strengthen a sustainable supply chain that allows us to grow together and share our achievements.

See the following link for Aichi Steel's procurement policy.

Strengthening of partnerships with suppliers

Every year in April, Aichi Steel holds the Hokokai* General Meeting to explain the business environment and company policies to major suppliers in Japan, and shares information on initiatives and goals regarding safety, compliance, and sustainability. We also provide support activities to each company by offering advice on safety, quality, and other issues according to their circumstances, and engage in improvement activities throughout the supply chain, such as mutual improvement through improvement case study meetings and the VA Exhibition as well as the horizontal development of good practices. To achieve carbon neutrality, in addition to study meetings with suppliers, our technical staff provides specific advice on energy saving initiatives at each company, and we work to advance our activities together with our suppliers.

- An organization consisting of suppliers aiming for mutual development based on partnership and mutual trust with Aichi Steel

Enhancement of supply chain resilience

Amidst rising geopolitical risks in addition to natural disasters and accidents, Aichi Steel is focusing on the stable procurement of raw materials and resources. By gaining information on the location, source of materials, and processes of our suppliers' manufacturing sites and quantifying the risks, we are taking necessary measures such as multi-sourcing and securing of inventories, while building structures that enable prompt initial response and recovery actions.

Strengthening of Relationships with Local Communities

Sustainable coexistence and co-prosperity with local communities

Aichi Steel aims for sustainable coexistence and co-prosperity with local communities. Recognizing our role as a good corporate citizen, we value communication through social contribution activities and other means to gain understanding and trust in our business activities, and work toward becoming a company that people want to remain in the area forever. Specifically, we are developing activities based on the four pillars: clean, green, creative, and volunteer support. Our ongoing initiatives include Cleanup Campaign, a community cleanup activity; flowerbed maintenance to maintain and improve the beauty of the rotary in front of Shurakuen Station; and the Lesson about Iron, held in cooperation with Tokai City, to encourage local children to learn about the potential and role of steel and foster their creativity. We also operate the Aichi Steel Volunteer Fund, encouraging employees and related parties to cooperate in fund-raising activities, and supporting volunteer activities by welfare organizations and facilities. These activities not only strengthen relationships with local communities, but also help employees to develop a mindset of solving social issues and provide feedback to our business activities. We will continue to expand the scope of our activities so that each and every employee can contribute to the realization of sustainable local communities.