Product

Gifu Plant Products

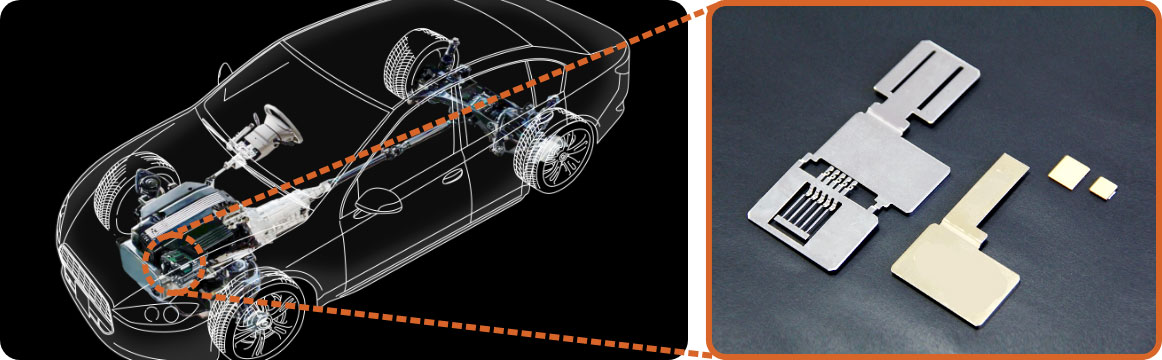

Each electric vehicle is equipped with an inverter that controls the power of the motor.

The lead frame is an essential component that provides efficient heat dissipation so that power modules in inverters can function stably.

We respond to customers’ requests with our high-precision press technology and plating technology that uses pure water.

Inverter for electric vehicle

Inverter for electric vehicle

Main Points of Electronic Component Manufacturing

- Water Treatment Equipment

That Can Strictly Comply with Wastewater Standards - When water used in the plating process is discharged outside the plant, it is purified by water treatment equipment in the factory.

Since the Gifu Plant area has strict regulations on wastewater, we conduct continuous composition analysis and created a system with stricter discharge standards than the prefectural standards in consideration of the environment. -

Water treatment equipment (1)

Water treatment equipment (1) Water treatment equipment (2)

Water treatment equipment (2)

- Total Inspection with Strict Standards in Clean Environment

- We perform image inspection using a camera and visual inspection of all products to confirm the plating quality and whether any scratches or foreign matter are present.

-

Clean room

Clean room Image inspection equipment

Image inspection equipment

- Carbon-neutral Model Plant

- In fiscal 2021, we achieved carbon neutrality through the early introduction of carbon-neutral city gas and bidding for non-fossil certificates.

The manufacturing division began operating its first on-site solar power generation system in May 2023. - Initiatives

to Achieve

Carbon

Neutrality