Society

Diversity & Inclusion

Basic approach

Aichi Steel believes that employees with diverse values, abilities, and experiences fulfilling their potential by accepting and learning from each other will lead to the creation of new value. To this end, we are committed to securing and training human resources and improving our in-house environment.

Mid-career recruitment

In these times of growing uncertainty, we believe that we need more advanced knowledge, diverse experience, and abilities than ever before in order to solve social issues with speed through our business. For this reason, we are focusing on mid-career recruitment, especially in our priority areas such as the DX field and research and development. In FY2024, we hired 7 employees in general positions. (Rate of mid-career recruitment: 28%)

Number of recruits (General technical staff)

Promoting advancement of women

Aichi Steel is committed to creating an environment in which women can choose flexible workstyles to pursue their goals. We support career development through training and other measures, and have adopted systems to help women balance work and life events. These include the Nice Family System, which is centered on childcare and nursing care support systems, as well as flextime system without a core period and working from home system. We are also focusing on awareness initiatives, such as providing e-learning on childcare support systems to all managers, in order to promote understanding in the workplace and among supervisors and make it easier for employees to take childcare leave regardless of their gender. As a result, the percentage of male employees taking childcare leave in FY2024 was 60.4%.

| FY2023 | FY2024 | ||

|---|---|---|---|

| Rate (and number) of female managers*1 | 1.3% (5 people) | 1.8% (6 people) | |

| Rate (and number) of male employees taking childcare leave*2 | 69.7% (53 people) | 60.4% (52 people) | |

| Wage difference between male and female employees*1 *3 (%) | All employees | 65.4% | 68.0% |

| Full-time employees | 68.2% | 70.3% | |

| Part-time/temporary employees | 62.0% | 65.3% | |

- Calculated based on the provisions of the Act on the Promotion of Women's Active Engagement in Professional Life

- Based on the provisions of the Ordinance for Enforcement of the Act on Childcare Leave, Caregiver Leave, and Other Measures for the Welfare of Workers Caring for Children or Other Family Members, calculating the percentage of childcare leave, etc. taken under Article 71-4, Item 1.

- There are no gender differences in our pay and evaluation systems, and any wage differences between men and women are due to factors such as length of service, the ratio of men to women in manager positions, and the ratio of men to women in different positions at different pay levels.

Senior employee participation

In view of the declining labor force and the need to maintain and improve on-site capabilities, we believe it is important to maximize the performance of our senior employees (aged 60+). We have established a “Nice Senior System” that allows all those who wish to continue to work after retirement age until their pension benefits begin. We are improving work environments and reviewing compensation packages while holding discussions with labor and management to ensure that senior employees can continue to work with a sense of security and a high level of motivation. We also conduct initiatives to help senior employees develop self-sustaining careers, including seminars on such topics as “Ways of Working,” “Retirement Benefits and Pensions,” and “Health and Diet” for those who have reached the age of 55, as an opportunity for them to rethink their future career plans and the meaning of work. Our post-retirement reemployment rate for FY2024 was 89% (65 out of 73 people).

Expansion of vibrant workplaces for people with disabilities

As well as systematic regular and mid-career hiring, we are taking various steps to enable employees with disabilities to play an active role in a wide range of workplaces, including manufacturing sites and administrative departments. With a focus on work motivation and how well each individual's unique characteristics fit the job description, we determine assignments based on a series of practical workplace training and interviews. We take various measures to fully utilize the potential of each employee even after their assignment, such as appointing a workplace mentor, holding regular meetings with the employee concerned, and providing follow-up support to their workplace. In addition, to eliminate obstacles making it difficult for employees with disabilities to work, we are also committed to expanding the number of workplaces available to them through the introduction of barrier-free facilities, support for career development, and initiatives to raise employees' awareness and improve understanding. With a focus on how well an employee's characteristics fit the job description, we determine assignments based on a series of practical workplace training and interviews.

Human Resource Development

Basic approach

Aichi Steel is committed to developing human resources who can improve their basic skills, which are needed in any environment, and their expertise necessary to adapt to changes, and are able to think and act independently, while practicing the Aichi Way, a set of shared values that must be held by all employees of the Aichi Steel Group whose key words are “Sustain,” “Appreciate,” and “Create.”

Strengthening basic skills and expertise

To strengthen the basic skills required for our operations, Aichi Steel is focusing on three areas: problem-solving capabilities, which are the foundation of work, skills for strong workplace capabilities, and digital literacy, which has been newly added. Our basic approach is to acquire problem-solving capabilities and skills through on-the-job training based on Genchi-Genbutsu (on-site experience) and to enhance their effectiveness through off-the-job training (group education, training, etc.) We provide digital literacy education mainly through e-Learning, with a menu of educational programs according to the proficiency level of each individual, thereby efficiently improving their skills. In addition, to support self-development efforts, we provide correspondence courses, study assistance, and certification incentive programs to strengthen expertise.

Skill improvement

We conducted PM practical skill training as part of rank-based training to improve employees' specialized knowledge and skills required for execution of operation. In addition, we support skill improvement by providing incentives, training environments, and information for technical skill tests that employees voluntarily take on.

Number of training instructors trained (cumulative)

Number of persons who passed the technical skill test

Efforts to develop human resources for executives

We are engaged in ongoing and systematic training to acquire new management personnel. To increase the self-awareness of the candidates, managing executive officers themselves serve as instructors, and the content focuses on mindset. In addition to equipping them with management and leadership skills that enable them to see and think from a companywide perspective and to create management ideas, we also hone their boldness, vision, sense of speed, and other qualities necessary for assuming higher responsibilities.

On-the-job and off-the-job training

We actively and systematically implement on-the-job training, based on the belief that experience and learning through “Genchi-Genbutsu” (on-site experience) are essential for human resource development. We have established a system in which each employee reviews their future career plan and regularly discusses with their superior their work assignments and goals for acquiring the skills and knowledge necessary to realize the plan and for developing competencies. Efforts are also made to enhance the effectiveness of our various training programs, such as managers and supervisors instructing junior employees to achieve a synergistic effect between on-the-job and off-the-job training, and top management giving talks on their own experiences to raise participants' motivation.

Digital literacy education

To maintain and improve competitiveness, we recognize that in addition to initiatives at manufacturing sites such as smart factories, we need to promote DX to transform our operations, organization, and corporate culture, and we are working to strengthen the development of our DX human resources. We are speeding up our development of DX leaders by conducting basic digital literacy education, and by determining the DX level of every employee through a DX assessment and using it to build a future education system. We are also working to promote DX companywide by holding events such as a Hands-on DX Exhibition, a Generative AI Application Contest, and on-site Copilot training sessions.

DX human resource targets

Initiatives to Respect Human Rights

Basic Approach

Respect for human rights in business has become increasingly important in recent years as we work toward achieving a sustainable society. Amid strong expectations for companies to conduct business with consideration for human rights, Aichi Steel is working to earn society's trust and be continually chosen by society at large by sincerely engaging with each of our stakeholders, including through activities that contribute to employee well-being, and by respecting the human rights of all people involved in our business operations.

Human rights policy

The Aichi Steel Group Human Rights Policy was established in March 2023 to define people-oriented management, including the company's common values, the Aichi Way, and to promote understanding and raise awareness both internally and externally. Based on the United Nations Guiding Principles on Business and Human Rights (UNGP), this policy is positioned as the highest level of human rights policy that all officers and employees of our group should comply with. Our suppliers and other business partners have also expressed their understanding and support for it.

See the following link for our Human Rights Policy.

Promotion structure

With the General Manager of the Corporate Planning Headquarters in overall charge and the Sustainability Promotion Department of Corporate Planning Headquarters as secretariat, the Human Resources Division, General Affairs Division, Purchasing Division, and other related divisions have collaborated to formulate action plans, share initiatives between divisions, and share and discuss social trends regarding human rights. They then report the details of these activities to the Top Management Meeting as appropriate. The Board of Directors monitor and supervise by receiving reports.

Promotion structure chart

Roles of each division

| Divisions | Roles |

|---|---|

| Human Resources Div. |

|

| General Affairs Div. |

|

| Purchasing Div. |

|

| Sustainability Promotion Dept., Corporate Planning Div. |

|

Roles of each meeting

| Meetings | Composition | Respect for human rights roles |

|---|---|---|

| Board of Directors | Chair: Chairman Outside Directors (2), Inside Directors (4) |

|

| Top Management Meeting | Chair: President Chairman, Executive Vice Presidents, In-house Company Presidents, General Managers |

|

Employee awareness and understanding

Based on our human rights policy, we actively conduct awareness-raising and dissemination activities aimed at realizing “people-oriented management.” In FY2024, our existing tiered human rights education, already conducted domestically, was expanded to our overseas group companies, promoting the practice of human-rights?respecting behavior across the entire group. In addition, through the annual Compliance Awareness Survey, we monitor employees' understanding and engagement while continuing our awareness-raising activities.

Human rights due diligence

To address human rights risks arising from our business activities, we mapped the human rights risks of the Aichi Steel Group based on information collected from domestic group companies, key business partners, and internal sources, then identified key issues and determined prevention and mitigation measures. In FY2025, we are implementing these measures and evaluating their effectiveness, working to reduce human rights risks throughout the supply chain.

Harassment prevention

This is not only an assault on personal dignity and a disturbance in the workplace, but also a problem that severely impacts business management. This is why labor and management are working together to create harassment-free workplaces. We have established the Aichi Steel Harassment Prevention Guidelines, which stipulate measures for preventing harassment and other matters for the company and employees to observe, and provide education to all executive officers and employees. We have also established dedicated consultation contact points internally and externally to address harassment issues, and we are allocating consultants in each workplace to systematically suppress harassment while achieving early detection and resolution. In FY2024, we received 14 consultation requests and reports. These are promptly examined and fact-checked by the Investigative Committee, which is comprised of members from both labor and management, and efforts are made to prevent recurrence, including strict action and education for supervisors. In addition, workplace counselors themselves raise awareness of harassment by regularly publishing "Counselor News" on the subject and distributing it to all employees, and by providing education on harassment to all employees.

Establishment of consultation desks

We have established a whistle-blowing system, an in-house hotline, and a human rights inquiry desk accessible to everyone. In FY2024, we clarified the responsible departments and procedures for handling each type of consultation. We have also set up a grievance mechanism for a wide range of stakeholders, including providing information to eligible employees about JP-MIRAI Assist, a consultation service available at Toyota Group companies for foreign workers. In FY2025, activities are underway to further improve the effectiveness of these consultation desks.

Major opportunities for dialogue with stakeholders

Roadmap for human rights initiatives

Health and productivity management

Basic approach

Aichi Steel has practiced people-oriented management since its beginning. People-oriented management focuses on supporting employees and their families in leading fulfilling and happy lives by promoting physically and mentally healthy, active lifestyles. Providing this foundation for our employees helps them play active roles within our company and make valuable contributions to society. Employee health and safety are a top priority, and we support both mental and physical well-being while promoting a people-friendly workplace.

Health declaration

Aichi Steel Health Declaration

We deliver materials that support society and aim to be a company that plays a vital role in the world. To that end, our management practices value our employees as irreplaceable assets and consider a healthy workforce to be a corporate strength.

- We place the highest priority on human health and take steps to extend the healthy life expectancy of our employees and their families.

- We aim to create a safe, hazard-free workplace and to foster an environment that supports both physical and mental well-being.

- We strive to be “a company full of smiles,” where employees care for one another’s health, support each other, and treat each other like family.

Promotion structure

Health management is a core element in our management strategy and we constantly strive for improvement. Our Human Resources Division, Safety, Health, & Environment Division, and other departments maintain positive relationships with health insurance associations and labor unions.

The president serves as the chair of the Central Safety & Health Committee and reports health plans and results to the committee. Important measures are submitted to the Top Management Meeting as necessary for approval and rolled out to the workplace and employees.

Safety and health committees at each worksite discuss with employees about site-specific measures and initiatives.

Health management strategy map and target indicators

Our company takes steps to create a workplace where every employee can thrive and perform at their best. We set targets and monitor progress using indicators such as the percentage of employees requiring follow-up medical examinations after health checkups, obesity rates, the number of employees experiencing high stress levels, and the number of sick leave days taken due to illness. We use engagement surveys and Single-Item Presenteeism Questionnaire (SPQ) developed by the University of Tokyo to comprehensively evaluate physical and mental health as well as job satisfaction.

Health management strategy map

Main initiatives

Health promotion

Health checkup program and follow-up measures

Aichi Steel maintains a 100% participation rate for mandatory general periodic health checkups. Follow-up measures after health checkups are tailored an individual’s level of health risk and include recommendations for follow-up examinations, secondary examinations under the Industrial Accident Compensation Insurance Act, lifestyle improvement guidance, and health seminars. Secondary examinations under the Industrial Accident Compensation Insurance Act are encouraged by providing convenient in-house services.

Regular health checkup participation rate (Aichi Steel)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Regular health checkup participation rate (%) | 100 | 100 | 100 |

Cancer screening

We support the early detection and treatment of cancer through services such as tumor marker blood tests and examinations, including gastric X-rays and gastroscopy, for esophageal and gastric cancer. For women’s health, we offer screenings for breast, cervical, and ovarian cancer.

Health Challenge 8

The Health Challenge 8 initiative aims to improve employee health by focusing on eight areas: maintaining a healthy body weight, eating breakfast, managing alcohol consumption, limiting between meal snacking, smoking cessation, exercise, sleep, and stress management.

Aggregate results of medical examination questionnaires (smoking, exercise frequency, etc.)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Healthy weight (BMI above 18.5 and below 25) (%) | 65.2 | 63.8 | 61.6 |

| Eats breakfast daily (%) | 79.6 | 80.7 | 80.6 |

| Does not smoke (%) | 68.9 | 70.2 | 71.3 |

| Exercises 30 minutes or more at least one day a week (%) | 38.1 | 38.9 | 41.0 |

Smoking cessation

We are implementing smoking cessation measures to reduce health risks for smokers and prevent health hazards from secondhand smoke for non-smokers. We began systematically prohibiting smoking at company sites in FY2023 and completely prohibited smoking at all company sites starting in May 2024. Smokers who wish to quit are provided with on-site group support from occupational nurses along with ongoing support through consultation sessions.

Health events (walking event, yoga class)

We hold regular walking events at Shiawase Mura in collaboration with Tokai City. At the events, we promote health awareness by presenting health check booths.

We also promote exercise by holding after-work classes in yoga, boxing workouts, and Pilates at Aichi Steel Gymnasium ASCOM.

Dietary education (dietary improvement seminars, healthy cafeteria menu)

The employee cafeteria offers menus rich in vegetables to promote nutritionally balanced diets that help prevent lifestyle diseases and support overall health. By providing healthy food options, we aim to help employees establish and maintain healthy eating habits.

Mental health care

Aichi Steel is working to prevent the occurrence of mental health issues and ensure their early detection and care by establishing a Mental Health Consulting Counter, providing education to both regular employees and supervisors, and providing consultations with a medical adviser on mental health for employees with mental health issues.

Stress checks

All employees receive annual stress checks. Physicians interview individuals with high stress levels to provide early preventive care. Worksites identified as high risk for stress receive feedback based on group analysis results to ensure they receive the support needed to maintain employee mental health.

Stress checks

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Examination rate (%) | 99.4 | 98.5 | 98.5 |

| High stress rate (%) | 7.8 | 8.6 | 8.6 |

Dedicated mental health support staff

We work to prevent issues and ensure early detection and early care through consultations with our consulting psychiatrist for employees experiencing mental health issues. Staff at the Mental Health Consulting Counter consult with employees who need support and provide guidance to supervisors and worksites with individuals with mental health issues. In fiscal FY2022, we revamped our return-to-work support program to better assist employees and worksites supporting individuals returning from leave for mental health reasons.

Health education

Job level-based health education

We incorporate mental and physical training into our training curriculum and provide sessions for employees when they join the company and when they are promoted. We provide e-learning sessions to help employees learn about their duties before joining the company, followed by on-the-job training centered on group discussions to promote effective skill development.

Specific health guidance

Measures to prevent development of lifestyle diseases include providing individualized health guidance following the criteria established by the Ministry of Health, Labour and Welfare. We are improving work-day accessibility to individualized health guidance and continue to work with health insurance associations to promote prevention of lifestyle diseases.

Age-based education at key life stages

We provide one-day education sessions for employees at ages 25, 30, and 35 years. These sessions are intended to help younger employees maintain and improve their health by making them aware of age-related health issues.

Safety

Basic approach

The Aichi Steel Group recognizes that safety takes priority over all. In accordance with our Basic Philosophy for Safety and Health, we aim to create a safe and secure work environment for everyone working on our premises, and to transform into a company with a safety culture.

Basic Philosophy for Safety and Health

Safe work, Reliable work, Skilled work. Safe work is “the gate” to all work. Let us pass through this gate.

Activity policy

To achieve “zero accidents”, the Aichi Steel Group is developing safety activities based on the three pillars of safety management, fundamentally safe designs, and the development of safety-conscious human resources.

Promotion structure

Recognizing that safety and quality are the foundation for creating added value, we promote companywide activities with the Risk Management Headquarters as the overall driving force. The Safety, Health & Environment Division plays a central role in safety, and based on the belief that all accidents and injuries can be eliminated, it strives to create a safe and healthy work environment for all employees on our premises by sharing companywide policies with our in-house companies, headquarters, Group companies, and cooperating companies.

Promotion structure chart

Prevention of occupational accidents

We conduct risk assessments aimed at eliminating occupational accidents. Especially for high-risk work that could lead to significant or serious accidents, we strive to prevent accidents by systematically implementing improvements through fundamentally safety measures that eliminate the causes and reduce the risks. For all occupational accidents, we work to prevent recurrence by clarifying the true cause, including the context, and informing the group and cooperating companies of the accident.

Number of lost time accidents and lost time frequency rate

Initiatives for FY2024

Safety management

Management safety inspection meeting

To accelerate safety initiatives, management goes to problem workplaces to understand issues first-hand through Genchi-Genbutsu (on-site experience).

Proactive prevention activities through Genchi-Genbutsu

Dedicated safety time is set aside for management supervisors to verify safety on site, where they focus exclusively on safety and engage in activities to identify workers' concerns.

Fundamentally safe designs

Reduction of high risk through risk assessment

We improve high-risk operations and equipment identified through risk assessments to make them safer and to promote accident prevention.

Introduction of equipment eliminating hazards and harmful factors

When installing new equipment or modifying existing equipment, we separate people from hazard sources from the planning and design stages to make it fundamentally safe and reduce risk.

Development of safety-conscious human resources

Safety key personnel training

Since 1995, we have conducted specialized occupational safety and health training to develop capable personnel who form the core of workplace safety and health activities, working to raise the overall level in safety and health management.

Training and drills

We have established an Anzen Dojo venue where employees can learn and experience the risk of occupational accidents at work using actual equipment and VR, as well as a Skill Competition where they can review, refine, and raise the level of their safety awareness and technical skills. We also hold joint disaster drills with the Tokai City Fire Department, simulating scenarios such as fires and explosions as part of our efforts to prevent industrial and occupational accidents.

Occupational health

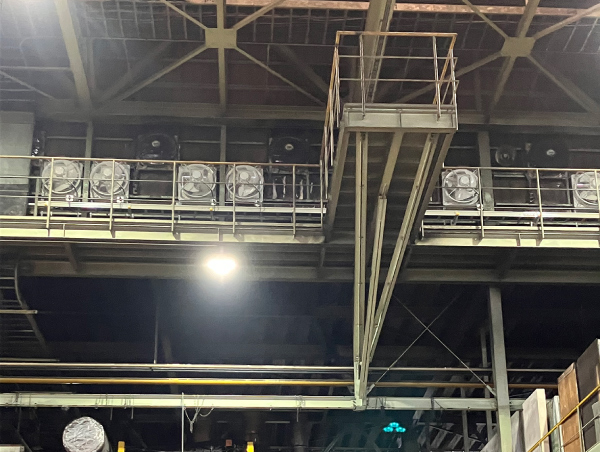

Heat environment improvement

We have improved working conditions by conducting risk assessments in response to recent climate change and strengthening heat countermeasures.

Stakeholder relations

Basic approach

See the following link for our multi-stakeholder policy. (Japanese language only)

Aichi Steel conducts its business activities through relationships with various stakeholders, so building positive relationships with those stakeholders is important for improving our corporate value. Through proactive dialogue with stakeholders, we are able to incorporate the needs of society and expectations for us into our business activities, and encourage them to feel a sense of closeness with Aichi Steel. In this way, we are able to grow alongside all of our stakeholders, including customers, shareholders and investors, employees, suppliers, and local communities.

Promoting dialogue with employees

Under the principle of “people-oriented management,” we create an environment in which each and every employee can feel secure and demonstrate their full potential, as we aim to provide value to society and achieve sustainable growth. To achieve high employee engagement, which is a source of value creation, we are promoting the development of rewarding workplaces and the evolution of our human resource system through continuous dialogue.

Built on mutual trust between labor and management, we hold labor-management meetings twice a year at the in-house company and headquarters levels to accelerate the pace of change through frank discussions to resolve issues that are relevant to the workplace. We continuously carry out initiatives that reflect employee feedback, such as identifying and rectifying issues from morale survey results, improving workplace conditions, and enhancing welfare benefits.

Specifically, through measures such as subsidizing workplace trips and social gatherings, and rebuilding dormitories for single employees, we aim to create a workplace where diversity is respected, openness is encouraged, and everyone can feel comfortable and gain a sense of fulfillment.

Initiatives and achievements for each stakeholder

| Stakeholders | Initiatives to promote dialogue | FY2024 results |

|---|---|---|

| Customers |

|

Number of inquiries 1,561

|

| Shareholders and investors |

|

Number of dialogues with

institutional investors (total) 45 |

| Employees |

|

Number of labor-management

roundtables and conferences22 |

| Suppliers |

|

Number of

participating companies 126 |

| Local communities |

|

Employee participation rate

in social contribution activities 80% |

Initiatives to improve engagement

Aichi Steel conducts an annual engagement survey of all employees. Based on the results of the analysis from various perspectives, such as motivation toward work, sense of growth through work, support from superiors, and workplace culture, we are working to develop various personnel measures and improve management in each workplace. In FY2023, we revamped the survey with the goal of deepening our analysis and clarifying issues for each workplace. We launched a new leadership training program in FY2024, incorporating responses to issues identified through the survey and enabling continuous improvement of workplace culture. Going forward, we are enhancing engagement by verifying the results of these efforts and addressing additional issues.

Changes in engagement evaluation

| Morale survey | Survey of employee attitudes toward company management and policies, work motivation, etc. (once every two years) |

|---|---|

| Office workplace management survey | Survey of attitudes of general workers to workplace management, relationships with supervisors and co-workers, etc. (once a year) |

| Workplace capability survey | Survey of attitudes of skilled workers to workplace management, relationships with supervisors and co-workers, etc. (once a year) |

Strengthening partnerships with suppliers

Superior raw materials, parts, and technologies supplied by our suppliers are essential for manufacturing Aichi Steel's products. Based on our belief that collaboration with suppliers is important in addressing various sustainability issues, we are working to build a relationship of trust with them through close communication, and to establish and strengthen a sustainable supply chain that allows us to grow together and share our achievements.

Every year in April, Aichi Steel holds the Hokokai* General Meeting to explain the business environment and company policies and share information on initiatives and goals regarding safety, compliance, and sustainability. In December 2024, we revised our Partnership Building Declaration to be more specific about coexistence and new partnerships throughout the supply chain, and adherence to fair business practices with subcontractors. It was distributed to all 126 member companies at the April 2025 Hokokai General Meeting to share a common understanding. We also launched new study group activities within the Houkokai in FY2024 to strengthen the entire supply chain, conducting workshops on the Subcontractor Act in July that year and on the realities of cyberattacks and key countermeasures in December.

- An organization consisting of suppliers aiming for mutual development based on partnership and mutual trust with Aichi Steel

See the following link for our Partnership Building Declaration. (Japanese language only)

Strengthening relationships with local communities

As a good corporate citizen, we recognize the importance of communicating with local communities through social contribution activities and so on, and are engaged with them in co-creation activities. Specifically, we are developing activities based on the four pillars: clean, green, creative, and volunteer support. Such activities not only strengthen our relationships with local communities, but also help develop a social issue solving mindset among employees and provide feedback on our business activities. We will continue working actively toward the realization of a sustainable local community, to which every one of our employees can make a contribution.

Clean

Cleanup activities conducted on Clean AICHI STEEL Day in areas surrounding domestic and overseas business sites

Green

Flowerbed maintenance conducted in front of Jurakuen Station to improve the area's appearance

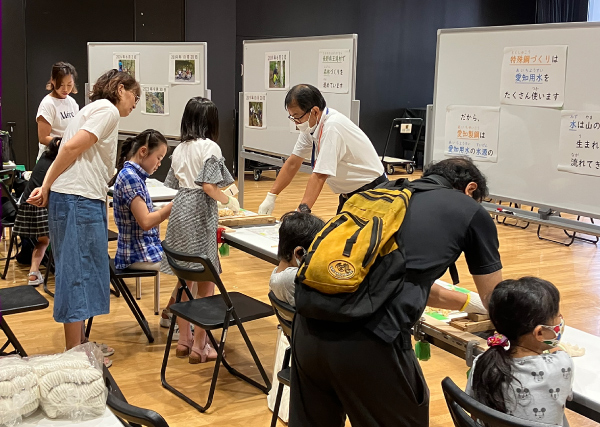

Creative

Hands-on classes and plant tours for elementary school students held at the Tokai City Monozukuri Dojo

Volunteer support

Operation of the Aichi Steel Volunteer Fund, which uses employee donations to contribute to local welfare facilities (We have also established a Matching Gift Program under which the company contributes the same amount)

Research and Development

Our company's technological development is rooted in our founding spirit, “Great cars are made with great steel,” and we are currently broadening this to include “A great society comes from great materials.” We believe our mission is to contribute to society through materials, regardless of the era.

In steel development, we are advancing the development of steel materials that allow for streamlined manufacturing processes and steel materials suited for eco-friendly products with reduced CO2 emissions, thereby contributing to the achievement of a decarbonized society.

As for stainless steel, we are expanding our product lineup of stainless steel deformed bars and duplex formed stainless steel, which contribute to extending the service life of energy and social infrastructure, as well as developing steel materials suited for a hydrogen society that are resource-efficient, low-cost, and highly safe.

Additionally, in the development of forged products, we are aiming to develop innovative processes that balance higher functionality with cost reduction for next-generation electric drive unit vehicles, along with more advanced forging technologies. We are also promoting DX initiatives utilizing digital technology to drastically accelerate development.

In smart business development, we are creating new materials and products for the evolving smart society, such as heat-dissipating components for automotive electronic devices, a magnetic positioning system using MI sensors, and magnets for motors. By leveraging the strength of our “integrated forging with steel making processes” that covers all processes from steel material production to forgings in-house, and our “materials business DNA” cultivated since our founding, we will continue to develop and commercialize new products that contribute widely to a sustainable society.

Company-wide standardization activities

Standardization enhances the convenience and safety of society as a whole by establishing common rules for specifications, testing methods, display methods, and other aspects of new products and technologies. This improves product reliability, leading to more industry collaboration and enhanced international competitiveness.

To promote R&D in line with these standardization efforts, we established a company-wide Standardization Promotion Committee in 2023, chaired by the Head of the Development Division, who also serves as CSO (Chief Standardization Officer). Department heads from each in-house company's business management division and heads of each development division participate as division-level coordinators, while representative managers from the relevant departments also serve as committee members. Centered on this committee, we promote strategic standardization while focusing on internal awareness and personnel development in standardization. We actively encourage young and mid-career employees engaged in business planning and intellectual property to participate in METI's Rule Formation Strategy Training and other programs.

In our FY2024 activities, for all four ongoing themes, individual review meetings were held between the theme leaders and the CSO to review past results and current issues, and to discuss in detail how to proceed going forward. The results were shared at the 2nd Standardization Promotion Committee briefing in June 2025, and future plans for all themes were approved.

Organization chart

Intellectual property

Basic approach

Aichi Steel has established proactive intellectual property (business expansion and challenges), defensive intellectual property (business stability), and basic activities (human resource development and structure building) as its priority policies, setting targets for each of these, and aiming for intellectual property activities that drive steady growth.

Promotion structure

Aichi Steel has established an Intellectual Property Committee to promote intellectual property activities. The committee is chaired by the Research and Development Headquarters general manager, with general managers of each in-house company, headquarters, and technology division as members.

Organization chart

Strengthening collaboration between development and intellectual property divisions

To date, we have focused our activities on protecting the intellectual property resulting from our R&D. In addition to this, we are working to improve the quality of our patent applications by reinforcing collaboration between our development and intellectual property divisions and submitting applications more strategically. We are expanding the scope of this collaboration, particularly for foreign patent applications which involve high costs, and aim to minimize costs and maximize benefits through thorough screening of each case, including the utilization of patent rights after they are granted. In this way, we pursue intellectual property activities that help to secure our competitive advantage and business expansion.

Quality and Production

Basic approach

Aichi Steel has always focused on the manufacturing capabilities of integrated forging with steel making processes, which cover everything from material design to production of steel, forged products, and electronic components. We have continued to provide our customers with highly functional and high-quality materials and parts with high strength, durability, and machinability, which are indispensable in the automotive and other industries. This stable supply of high-quality, low-cost products has been supported by the implementation of quality management and the evolution of manufacturing capabilities through the Toyota Production System (TPS), Total Quality Management (TQM), and Total Productive Maintenance (TPM). Using this as a foundation, we are working to build production systems that are resilient to changes as we face increasing uncertainty, including geopolitical risks and sharp price fluctuations.

TPS activities

Aichi Steel is striving to improve its efficient manufacturing capabilities by promoting cost reduction through thorough elimination of waste based on the two pillars of TPS: just in time (JIT) and automation. The in-house companies systematically address improvement themes for cost reduction identified from the perspective of TPS, and their results are shared companywide through a TPS convention held at the end of the fiscal year.

We have established a TPS trainee system to implement TPS, where we focus on human resource development. We train personnel selected as TPS promotion leaders through classroom lectures as well as practical learning, including case studies, in order to effectively apply TPS methods in the workplace. Also, to facilitate the smooth introduction of TPS to our production sites, we are promoting the acquisition of TPS methods appropriate to the role of each employee by providing a wider range of level-based training. With these two activities, cost reduction and human resource development, we are building flexible production systems that are resilient to change.

TQM activities

Implementation of quality management based on TQM

Based on the fundamental TQM principles of “customer first,” “full participation,” and “constant improvement,” the Aichi Steel Group is engaged in TQM activities to implement quality management. This is done by “improving the quality of products and work” and “increasing the vitality of people and the organization.”

To consistently meet quality requirements

The automotive industry is undergoing a once-in-a-century transformation, and its quality requirements are also changing. We are always trying to maintain and strengthen our competitiveness by delivering the level of quality that is required. One such initiative involves developing experts in technologies such as IoT, big data, and AI through the Toyota Group Machine Learning Practice Dojo. So far, we have trained 2 Shihan* (master instructors) and 3 Shihan-dai* (assistant instructors).

- Shihan (Master Instructor): Top talent in Toyota Group

Shihan-dai (Assistant Instructor): Associate top talent in Toyota Group

QC circle activities with full participation

Aichi Steel is working to establish and expand our QC circle activities as a means of improving operations in workplaces. We are working to develop human resources and revitalize our organization through consistent team efforts to identify problems, clarify issues, and formulate and implement countermeasures. In FY2024, 167 circles conducted activities, and 11 cases received external awards. For ingenuity and creativity proposal activities by individuals*, we set a target of at least one proposal per month, and all employees achieved the target throughout the year. As a result of these efforts, in FY2024 we received four awards from the Minister of Education, Culture, Sports, Science and Technology.

- Activities to encourage and evaluate employees' suggestions on how to improve the efficiency and quality of daily operations. Rewards are given based on the size of the effect, the number of proposals per year, and other factors in order to increase employees' motivation.

Improvement themes (QC circle)

| Topics | Composition |

|---|---|

| Labor-saving | Improvement of single-person productivity per day, consolidation of equipment |

| Shortening of lead time | Reduction of production lot sizes, streamlining of production |

| Enhancement of production potential | Reduction of downtime, improvement of specific consumption |

| Reduction of man-hours | Reduction of downtime, shortening of MCT* |

- Time required to machine and assemble a single part (Machine Cycle Time)

TPM activities

We are committed to TPM activities to ensure efficient production of high-quality products. Based on the three key concepts of “full participation,” “initial cleanup,” and “HR with strong technical capabilities,” we aim to transform people's behavior and on-site facilities to achieve zero breakdowns and zero defects by analyzing, addressing, and improving production facilities before breakdowns occur. With operator self-maintenance as the most important activity, we have set quantitative targets for activities such as three zeros in equipment failure, quality defects, and occupational accidents, and productivity improvement through the reduction of production losses.

In FY2024, the number of Level 1 Certified Autonomous Maintenance Technicians reached 360, an increase of 91 from the previous year (certification rate: 31.1%). We have achieved steady results, including a 27.0% reduction in total facility failures (compared to FY2021.) To further promote and strengthen our TPM activities, we will work on improving quality and maintaining an efficient production system, such as by using DX for data analysis and visualization.

AICHI-style TPM Gold Award Model development

This model is for enhancing autonomous maintenance activities by utilizing DX and karakuri mechanisms, with a focus on Genryou Management* and utilization of aging facilities. Activities began in FY2023, and in FY2024, the binding machine in the Hagane Company's Steel Bar Rolling Section, and Line 31A of the Kitaeru Company's 3rd Forging Production Sect. received Gold Awards.

- Genryou Management (managing with limited order quantity) Management that achieves efficient production with limited personnel and equipment, lowering the break-even point and building a profitable business structure.